The process begins in this moment, when the materials are ready to be processed.

The Business

Bonani S.p.a is a European leader in the production of three-phase and single-phase asynchronous electric motors, self-braking motors with DC and AC brake, two-speed motors.

Made in Italy

Export

adHoc Products

Our production process

1. Arrival of materials and storage

2. Production of crankshaft

At first the crankshafts are created for storage. At this stage we see a standardization of the cranckshafts that then come, in the second phase, equipped with different rotors according to the customer’s order.

3. Processing of the carcasses

Insertion of the hot winding takes place, the carcasses dilates so the material isn’t stressed.

4. Mechanical assembly

This phase Includes shaft balancing and bearing assembly. We begin to see the engine formed.

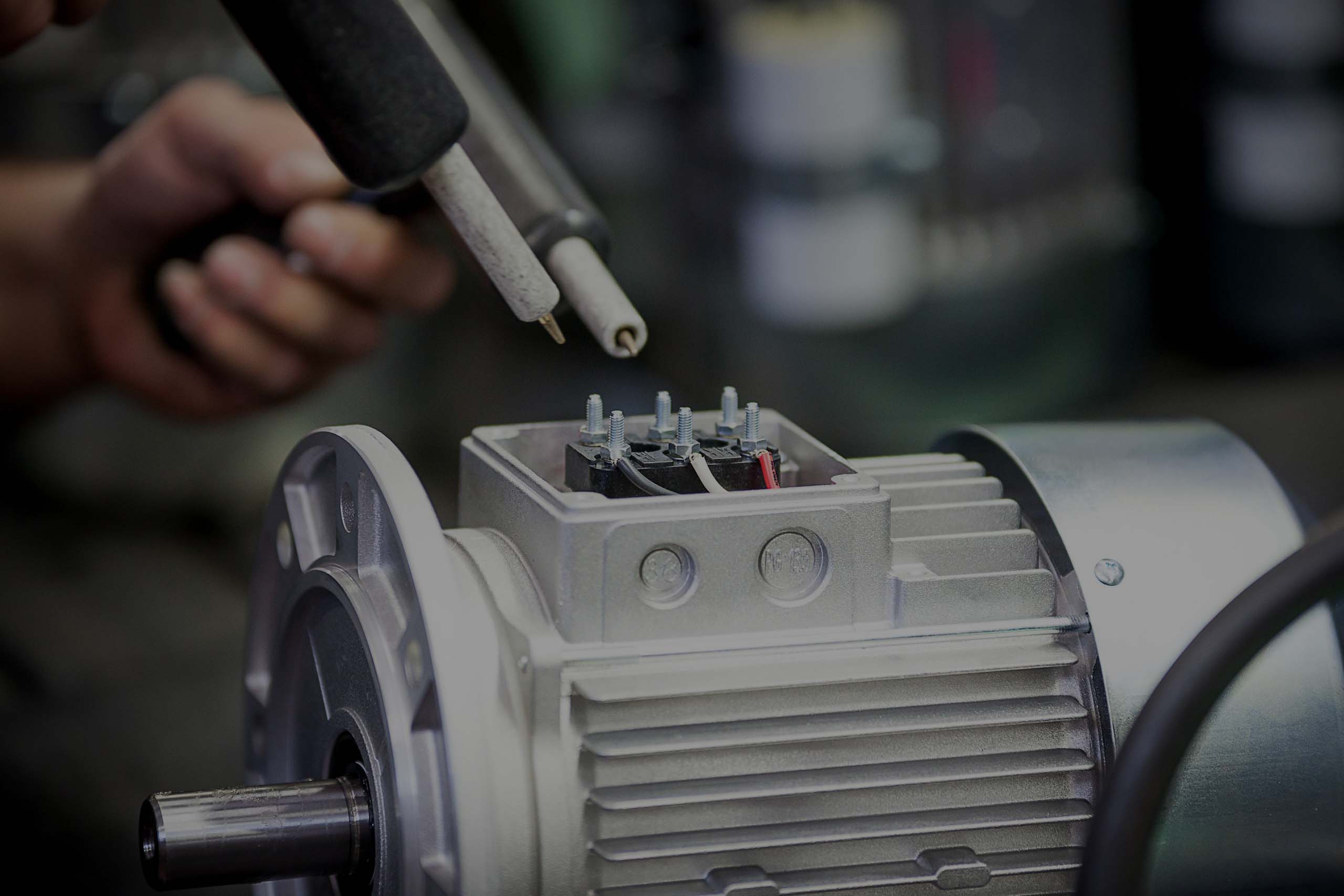

5. Wiring and testing

In this phase the mechanical assembly ends and the engine is tested.

6. Painting on request

The mechanically ready product is finished upon request.

7. Packaging and shipping department

The motor is packed and ready to be shipped.

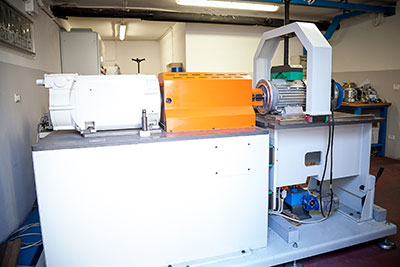

8.Test Room- Research and Development

Our Test Room helps us guarantee the best performance of the engine, according to our mission of incessant improvement of techniques and products.

1. Arrival of materials and storage

The process begins in this moment, when the materials are ready to be processed.

2. Production of crankshaft

At first the crankshafts are created for storage. At this stage we see a standardization of the cranckshafts that then come, in the second phase, equipped with different rotors according to the customer’s order.

3. Processing of the carcasses

Insertion of the hot winding takes place, the carcasses dilates so the material isn’t stressed.

4. Mechanical assembly

This phase Includes shaft balancing and bearing assembly. We begin to see the engine formed.

5. Wiring and testing

In this phase the mechanical assembly ends and the engine is tested.

6. Painting on request

The mechanically ready product is finished upon request.

7. Packaging and shipping department

The motor is packed and ready to be shipped.

8. Test Room- Research and Development

Our Test Room helps us guarantee the best performance of the engine, according to our mission of incessant improvement of techniques and products.

“Our biggest satisfaction comes from our custumers, who have chosen us for over 50 years for one reason: the excellence of our completely Made In Italy products. As far as quality is concerned, we don’t accept compromises”